Geothermal

Cladtek continues to diversify its product and solution offerings in the renewables sector, most notably across Geothermal applications.

Our weld overlay components have proven highly cost-effective compared to solid high nickel alloys and at the same time the clad enables the optimal selection of materials.

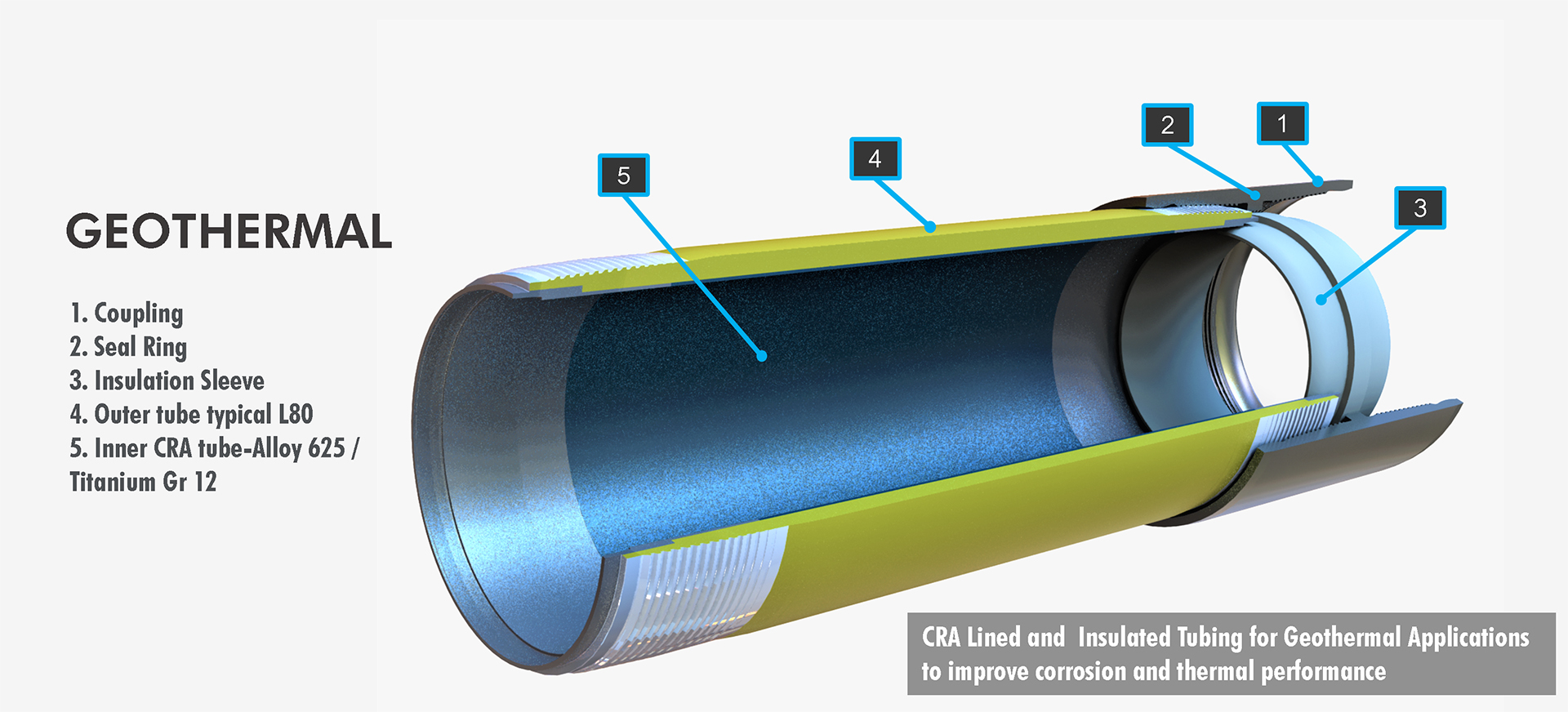

The CRA lined and insulated tubing for Geothermal applications reduces corrosion and increases thermal performance.

Steam Gathering Flowlines

- CRA Mechanically Lined Pipe (MLP) up to 30” and HeliClad pipe from 32” to 60” are the ultimate solution in terms of cost, reliability and installation performance.

- Compared to solid CRA and Metallurgically Clad pipes MLP and HeliClad have less than 50% of the CO2 emissions in the supply chain.

- MLP and HeliClad can be disposed of profitably at end of life, because the carbon and alloy can be separated and recycled.

Valves

Cladtek develops Process Valves for Geothermal with the following benefits

- Lower cost with competitive lead times compared to solid CRA valves

- Improved temperature related derating performance

- Use only the alloy you need for the wetted areas

- Use hard facing to combat erosion in susceptible areas

Process Piping

Advantages of Cladtek’s Process Piping are numerous with the key aspects being:

- Weld overlay (WOL) components are very cost effective compared to solid high nickel alloys like 625 and C276

- WOL can also be cost effective against Duplex and Super Duplex in high temperature applications due to reduced temperature related derating

- Clad enables optimal selection of materials

Down Hole Tubulars

The features of Down Hole Production Tubing and Liners include:

- Alloy 625 lined tubing up to 20” diameter

- Titanium Grade 12 lined tubing under development

- Extremely cost effective compared to solid CRA and Titanium Alloy liners

- Technology is economically scalable to larger diameters – less attractive for small bore below 6”

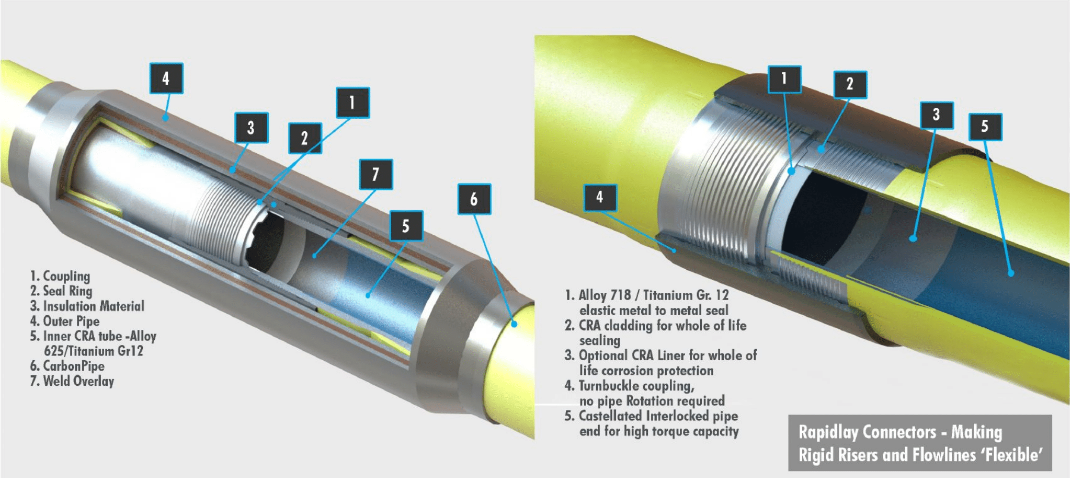

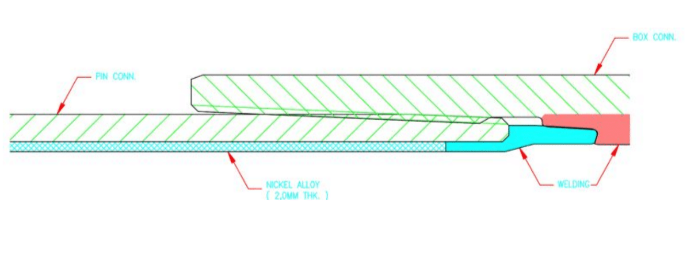

First lined OCTG

The SEAL-LOCK APEX is a threaded and coupled non-upset premium connection. Designed and tested for HPHT wells and critical service applications using CRA material.

- Transition connector: 7” 26ppf 4140/4340 85 ksi SLXD Box X BTC Box

- Tubing 7” 26ppf L80 SLXD Pin x Pin, 30ft

- Connector/coupling 7” 26ppf 4140/4340 SLXD