Risers

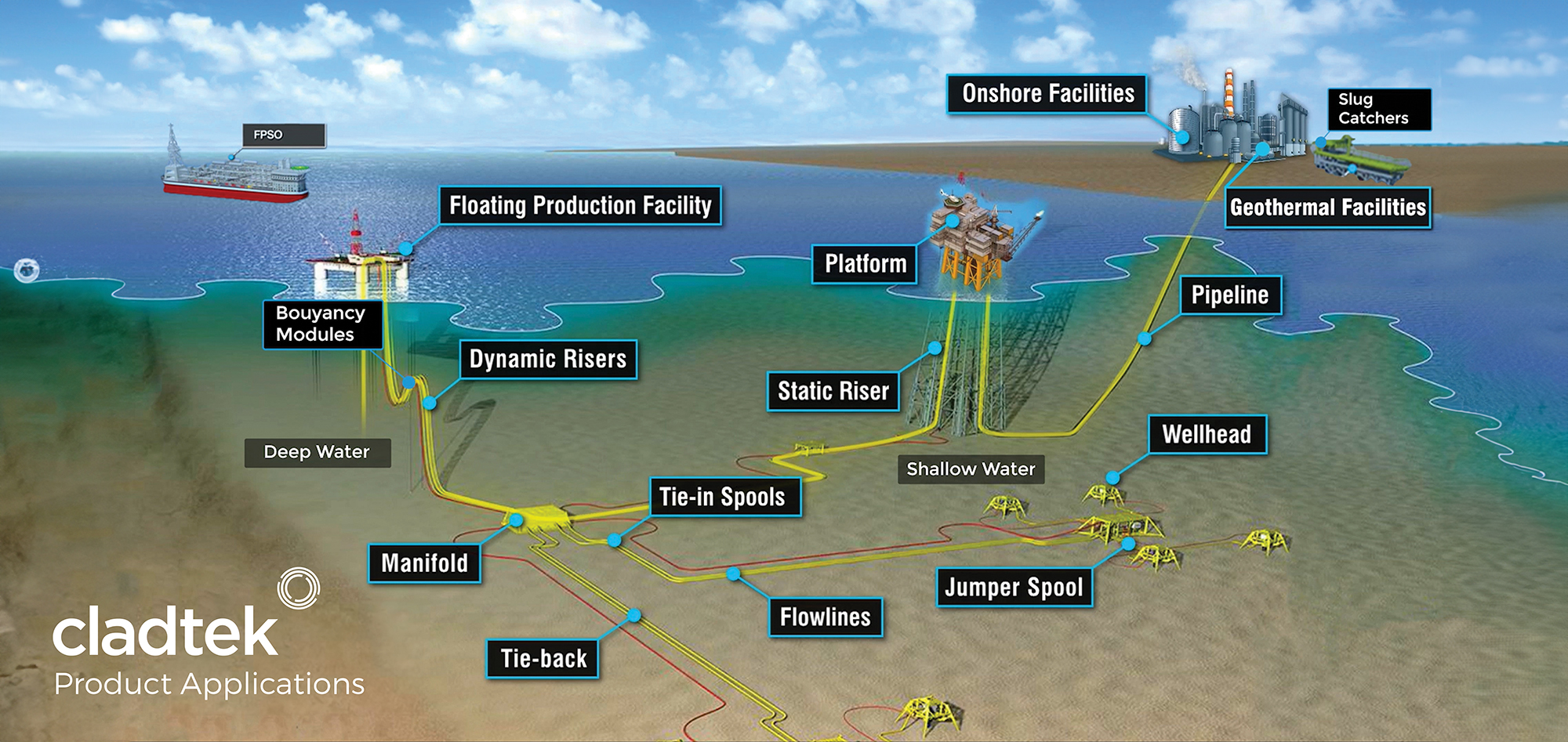

Risers are used to connect between the subsea field developments and the production facilities such as FPSOs or Semi-Submersibles. Similar to pipelines or flowlines, risers have several uses; in production, injection, and or export risers. Some risers are designed for alternating service, hence risers transport various fluids from full well fluids including any corrosive elements such as CO2 and H2S through to injection chemicals and stabilised oil and gas for export. Risers are often insulated for flow assurance, and can be either rigid or flexible.

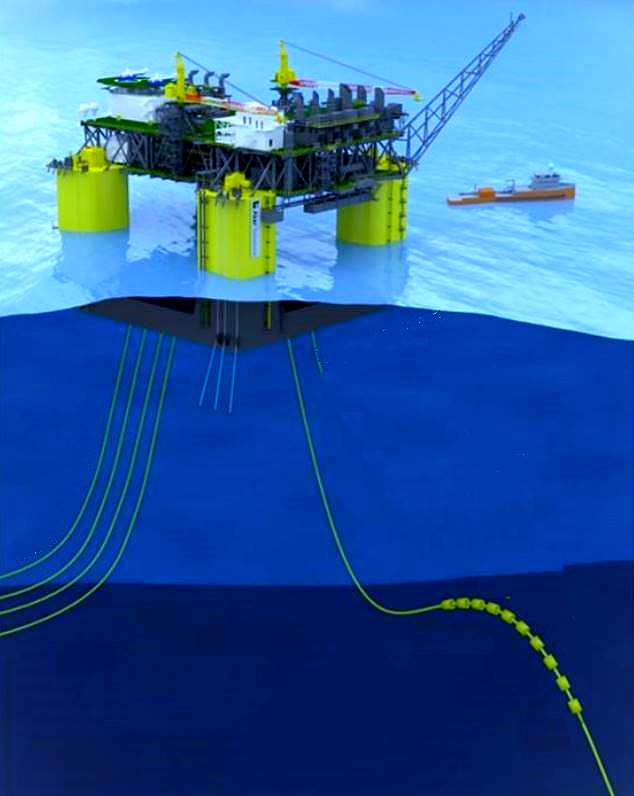

The majority of deepwater fields have traditionally been developed using flexible risers. However, rigid riser solutions today offer a more reliable and cost effective solution which lasts the life of the subsea field.

Cladtek’s MLP can be used in various offshore fields as rigid risers. Most recently, it is being used in the Mero-1 pre-salt field in the Santos basin at a water depth of 2,100 meters in a steel lazy wave riser configuration. This will be the deepest water application for any MLP. Dynamic risers in high-pressure, high temperature (HP/HT) service in deep water is considered the most demanding subsea application.

Cladtek’s MLP can also be deployed in any other type of rigid riser designs such as steel catenary risers, static risers and dynamic risers. Speak to us today to find out how our MLP with industry leading fatigue performance can work for your project.