Mechanically Lined Pipe (MLP)

In the ever-evolving oil and gas industry, the demand for cost-effective solutions that can withstand harsh operating conditions is on the rise. One such solution that has gained popularity is the use of Mechanically Lined Pipe (MLP). This consolidated technology combines the advantages of the CRA liner material with the strength and toughness of the carrier resulting in a product that offers performance, durability, and cost-efficiency.

In 2004, during our initial stages, we pioneered the addition of weld overlay ends to Mechanically Lined Pipes, setting a standard specification that operators now require. By the following year, we successfully manufactured the smallest Mechanically Lined Pipe with a 4” diameter. In 2011, we reached a milestone by fabricating our largest Mechanically Lined Pipe for ExxonMobil. Most recently, we just finished supplying 90 km of Mechanically Lined Pipe for Mero 1.

Understanding Mechanically Lined Pipe

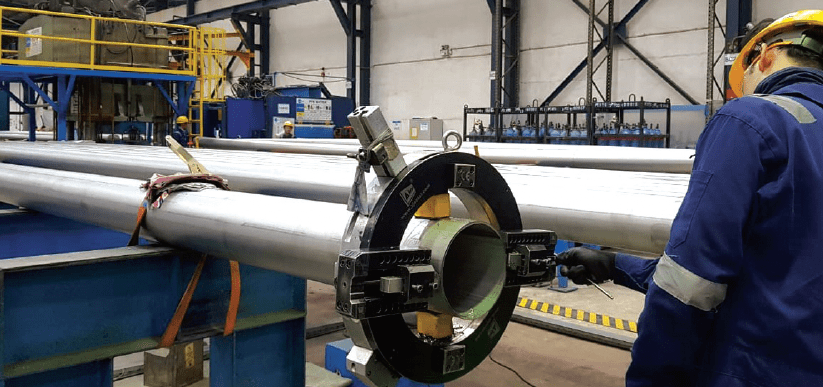

MLP is a type of bimetallic pipe that consists of an outer carbon steel carrier pipe with an inner layer of corrosion-resistant alloy (CRA). The CRA layer provides the required resistance to the aggressive conveyed medium, while the carbon steel pipe provides the necessary structural strength and toughness. These two materials are mechanically bonded together through mechanically interference, with both ends being finished with weld overlay cladding for improved fit-up and installability.

Benefits of Mechanically Lined Pipe

MLP offers several significant advantages over other pipe solutions:

- Durability and Longevity: MLP combines the strength of carbon steel with the corrosion resistance of CRA, resulting in a highly durable and long-lasting pipe solution. The mechanically lining process ensures a tight bond between the two materials, minimizing the risk of delamination or separation. MLP has proven to have better assurance on the component’s integrity.

- Versatility: CRA Clad Mechanically Lined Pipe can be customized to meet specific project requirements. It can be manufactured in various sizes, pressure ratings, and CRA alloy compositions, making it suitable for a wide range of applications in the oil and gas industry.

- Ease of Installation: MLP is designed for easy installation, reducing overall project time and costs. It can be easily welded, flanged, or coupled, offering flexibility and convenience during the installation process.

- Reduced Maintenance Costs: MLP requires minimal maintenance and inspection compared to other pipe solutions. The corrosion-resistant CRA layer provides long-term protection, reducing the need for frequent repairs or replacements.

- Cost-Effectiveness: One of the primary reasons for the increasing popularity of Mechanically Lined Pipe is its cost-effectiveness. Compared to solid CRA pipes, MLP offers a more budget-friendly alternative without compromising on performance or longevity. This cost-efficiency is especially beneficial for long-term projects with high corrosion risks. Compared to other CRA alternatives such as Solid CRA, MLP has proven to be up to 50% cheaper.

Applications of Mechanically Lined Pipe

CRA Clad Mechanically Lined Pipe finds applications in various areas within the oil and gas industry. Mechanically Lined Pipes can be used on a variety of pipelines/flowlines, which includes;

- Offshore Pipelines: In offshore environments, where pipelines are exposed to harsh conditions and corrosive fluids, CRA Clad Mechanically Lined Pipe offers a reliable and cost-effective solution. It can withstand high pressures, resist corrosion, and maintain its structural integrity over the long term.

- Subsea Pipelines: For subsea pipelines, CRA Clad Mechanically Lined Pipe provides superior corrosion resistance and durability. It can withstand the challenging conditions of underwater environments, including exposure to saltwater and corrosive chemicals.

- Sour Service Pipelines: In sour service applications where pipelines come into contact with hydrogen sulfide (H2S), CRA Clad Mechanically Lined Pipe offers excellent resistance to sulfide stress cracking (SSC) and hydrogen-induced cracking (HIC). It ensures the safe and reliable transportation of sour gas and oil.

- Water Injection Pipelines: Water injection pipelines require materials that can withstand the corrosive effects of water. CRA Clad Mechanically Lined Pipe provides the necessary corrosion resistance and structural strength needed for efficient water injection operations.

Mechanically Lined Pipes can also be applied for;

- Geothermal: Mechanically Lined Pipes offer great corrosion, temperature and abrasion resistance that would suit Steam Gathering Flowlines, Process Piping, Downhole Production Tubing and Liners and Water Reinjection Lines as mentioned above.

- Carbon Capture, Utilization & Storage (CCUS): Mechanically Lined Pipes can be applied to CO2 transportation pipelines, injection wells, and storage infrastructures where it would distribute CO2 within the storage reservoir.

- Risers: The application of mechanically lined pipes to risers offers a versatile and durable solution, addressing challenges related to corrosion, abrasion, temperature, and chemical exposure.

Cladtek’s Capabilities on Manufacturing Mechanically Lined Pipe

Cladtek offers Mechanically Lined Pipes within the range of these specifications;

- Size: 4” – 36”

- Carbon Steel Outer Pipe: API 5LB, HYCS, LTCS in SMLS, ERW, HFW/HFI, LSAW

- CRA Liner: 316L, 317LMN, 6 Mo, 904L, Duplex, Alloy 825, Alloy 625

- Length: 6 m, 12m, DJ (24m) or custom length

- Specification: API 5LD, DNV ST-F101 and Project Specification

Cladtek Mechanically Lined Pipes complies with;

- DNV ST-F101: Submarine Pipeline Systems

- API 5LC: CRA Line Pipe

- API 5LD: CRA Clad and Lined Steel Pipes

Cladtek: Your Partner for CRA Clad Solutions

When it comes to Mechanically Lined Pipe, Cladtek is a trusted industry leader. With its commitment to excellence and innovation, Cladtek offers a wide range of cost-effective solutions in the form of CRA Clad pipes, fittings, flanges, and joints to deliver a complete scope of clad piping suitable for both subsea pipeline or subsea production system projects.

- Weld Overlay: Specializes in weld overlay solutions, where a layer of CRA is applied to the internal surface of a carbon steel pipe through welding.

- Clad Induction Bends & Spools: Offering cladded induction bends and spools that are designed to withstand high pressures and corrosive environments.

- Commitment to Quality and Customer Satisfaction: We are committed to delivering high-quality solutions that meet the unique requirements of each project. With a focus on sustainability and customer-centricity, Cladtek ensures that its products are manufactured to the highest industry standards.

Conclusion

Mechanically Lined Pipe is a cost-effective and reliable solution for the oil and gas industry. It offers the perfect balance between corrosion resistance, structural strength and affordability. With Cladtek as your partner, you can trust in their expertise and commitment to delivering high-quality CRA Clad solutions that meet your project’s specific needs. Embrace the advantages of Mechanically Lined Pipe and experience long-term success in your pipeline projects.

- For Inquiries about our products, email us at info@cladtek.com

- To learn more about our recent milestones, click the link: Recent Milestones

- To know more about us, check our LinkedIn.