RapidLay

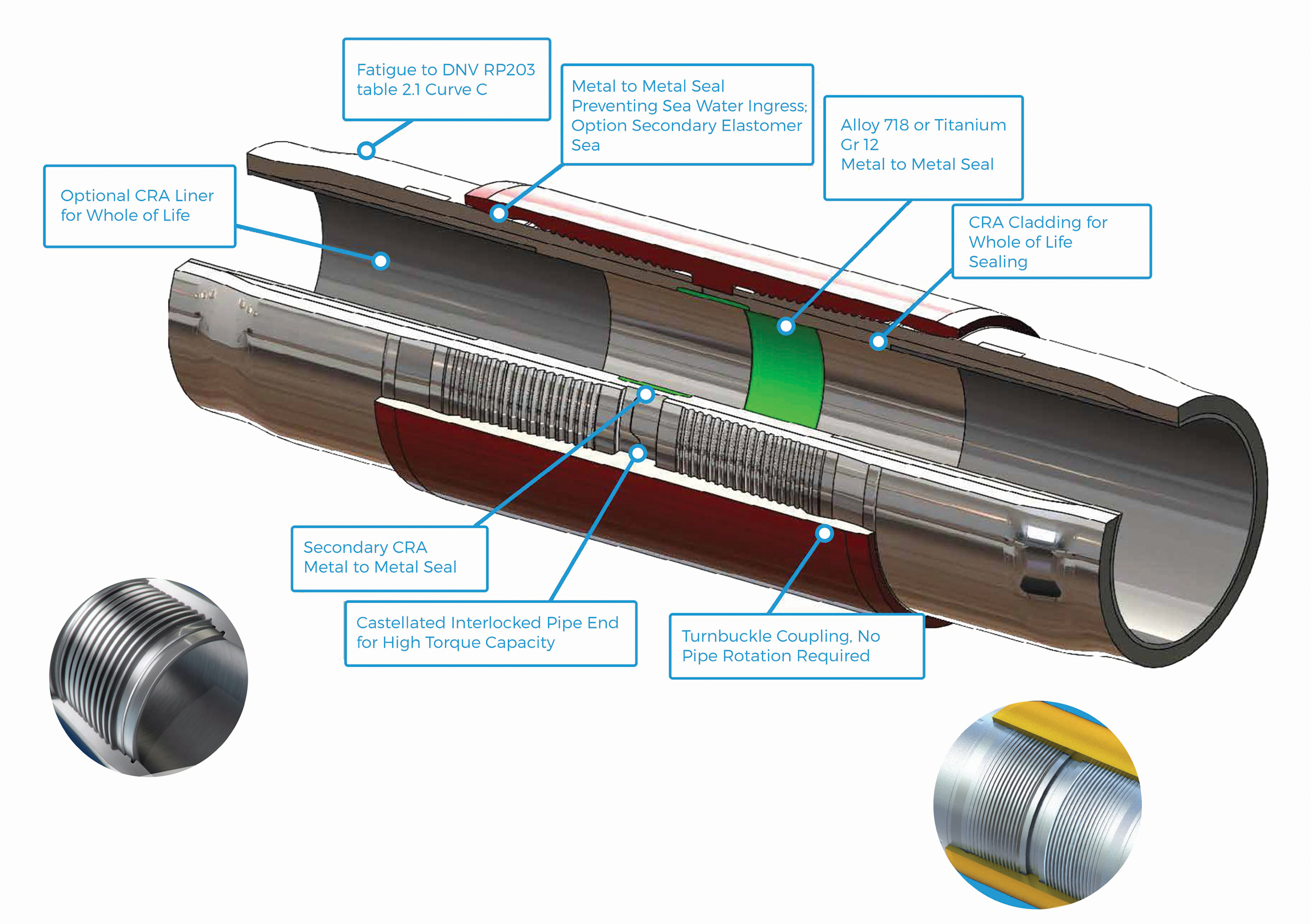

Cladtek’s RapidLay flowline connector technology provides a robust alternative to traditional welded flowline solutions, at substantially lower cost.

Installation of flowlines offshore using conventional welding solutions requires specialist equipment and is time consuming, elevating the installed cost of flowlines

Screwed connectors provide much faster installation and much lower dependence on specialist installation equipment. With simpler equipment and more installation spread options, costs can be substantially reduced.

The CladtekRapidLay connector system couples tried and tested aspects of existing technologies from the drilling industry and used with OCTG, with Cladtek’s CRA cladding expertise, and the success of earlier coupling systems such as the S2000, to overcome any risk of loss of integrity of the joint due to issues of corrosion from seawater ingress at the sealing surfaces, or uncoupling due to external torsional loads. can be used in both static and dynamic service and with a wide range of flowline materials. They are well suited to CRA clad and lined applications.

Couple RapidLay connectors with Cladtek Mechanically Lined Pipe (MLP) to fully optimise the performance and cost of your flowline solution in corrosive service applications.

Rapidlay Features and Benefits:

- Positive mechanical interlock

- Non-rotating metal to metal reusable Seal

- Protected seal surfaces

- High fatigue life

- No welded connection

- Easy stabbing and makeup

- High external torque resistance: cannot unscrew

- No risk of galling, reduced spares requirement

- Reduced Damage

- Suitable for dynamic service

- Can use high strength materials

- Fast installation offshore

- Relatively low cost, means fast return on investment

RapidLay technology connectors can be used in both static and dynamic service and with a wide range of flowline materials. They are well suited to CRA clad and lined applications.

Couple RapidLay connectors with Cladtek Mechanically Lined Pipe (MLP) to fully optimise the performance and cost of your flowline solution in corrosive service applications.